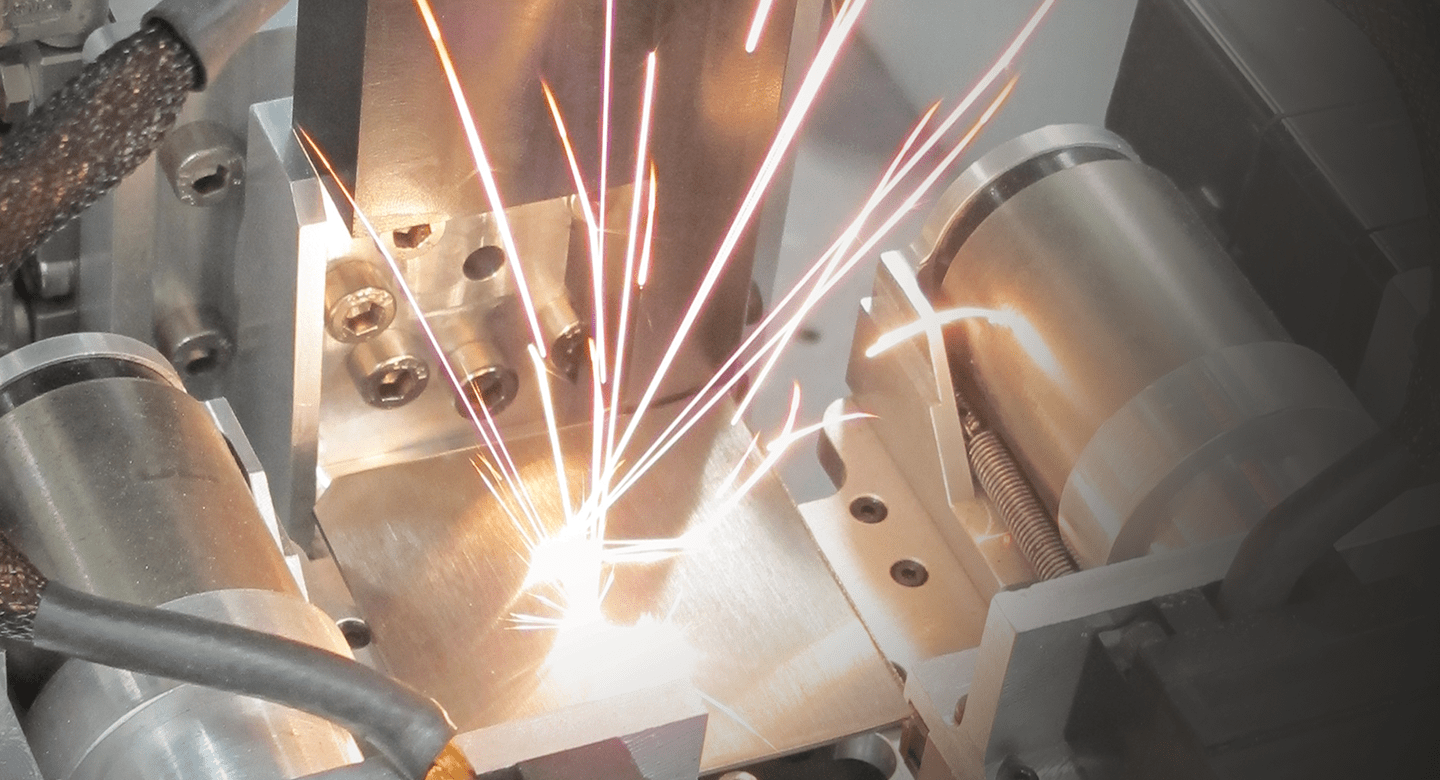

Laser welding is the process of joining two objects together through the use of a focused light beam. Laser welding is now being used to create medical devices with precision and accuracy. This process has many advantages over traditional laser welding medical devices, such as increased speed and accuracy, reduced heat and material waste, and improved product quality.

Image Source:Google

Reduced Heat and Material Waste: Traditional welding methods require the use of high temperatures and pressure to join the two objects. This can cause heat damage to the surrounding materials, resulting in material waste. Laser welding, on the other hand, does not require high temperatures or pressure. This drastically reduces the amount of heat and material waste, resulting in a much more efficient process.

Improved Product Quality: The accuracy and precision of laser welding also result in improved product quality. The laser beam is focused on the exact location where the two objects need to be joined, which ensures that the parts are joined correctly and securely. This results in a product that is much more reliable and durable.

Cost Savings: The improved speed, accuracy, and quality of the laser welding process result in significant cost savings. The process is much more efficient than traditional welding methods, which reduces the amount of time and materials needed for the project. This ultimately results in reduced costs for the manufacturer and a higher quality product for the consumer.